Mashiinnada Fasaxidda Joogtada ah

Faa'iidooyinka

1, balaastigga caaga ah ee usha quudinta ee hoos timaada xoogga is jiid jiid iyo heerkulka sare kaas oo meesha ka saaraya cilladaha gudaha ee usha lafteeda si buuxda si loo hubiyo in alaabta ugu dambeysa ay leedahay wax soo saarka badeecada ugu fiican iyo saxnaanta cabbirka sare.

2, aan preheating ama annealing, alaabta tayada wanaagsan helay by habka extrusion isticmaalka tamarta hoose.

3, oo leh hal cabbir oo usha quudinta, mashiinku wuxuu soo saari karaa cabbir ballaaran oo badeecooyin ah iyadoo la adeegsanayo dhimasho kala duwan.

4, khadka oo dhan si fudud oo degdeg ah ayaa loo shaqeeyaa iyada oo aan wax shaqo ah oo culus ama wasakhayn inta lagu jiro extrusion.

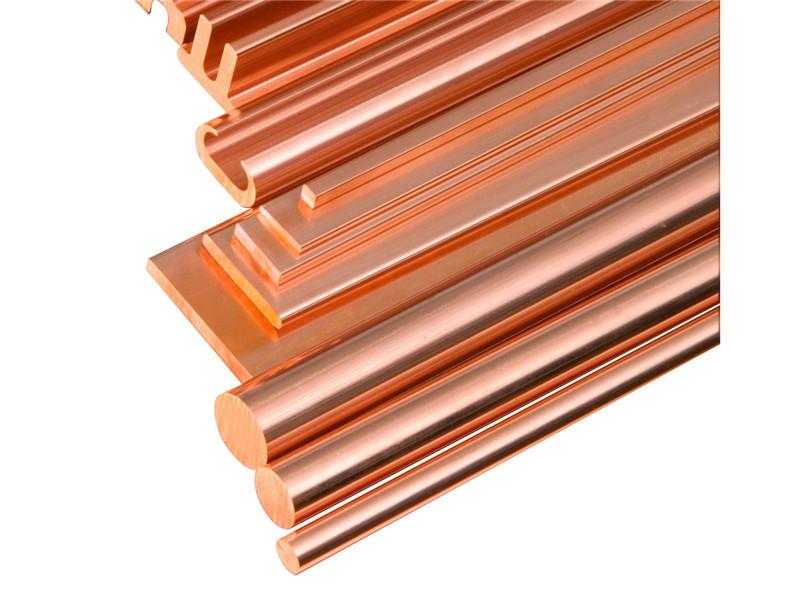

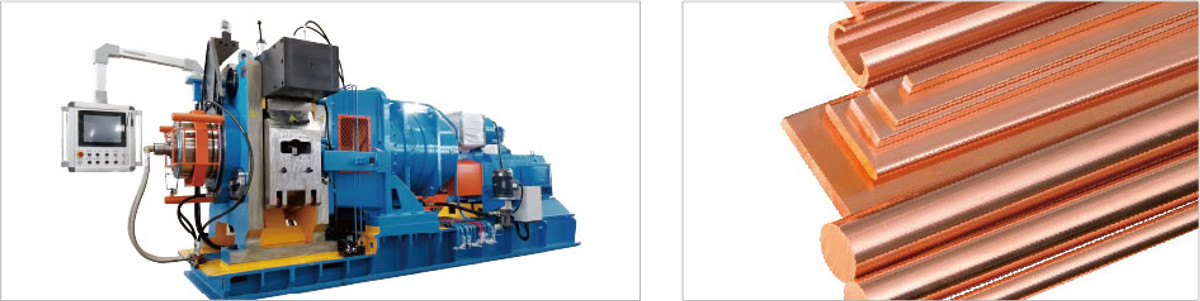

Quudinta usha naxaasta ah

1. Si aad u samayso fiilooyin siman oo naxaas ah, bas yar oo naxaas ah iyo silig wareegsan

| Qaabka | TLJ 300 | TLJ 300H |

| Awoodda ugu weyn ee matoorka (kw) | 90 | 110 |

| Usha quudinta dia. (mm) | 12.5 | 12.5 |

| Max. ballaca alaabta (mm) | 40 | 30 |

| Flat Wire Cross-Sectional | 5-200 | 5 -150 |

| Wax soo saarka (kg/h) | 480 | 800 |

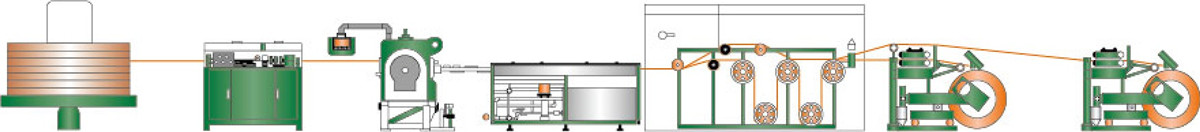

Qaabka Khadka Wax-soo-saarka

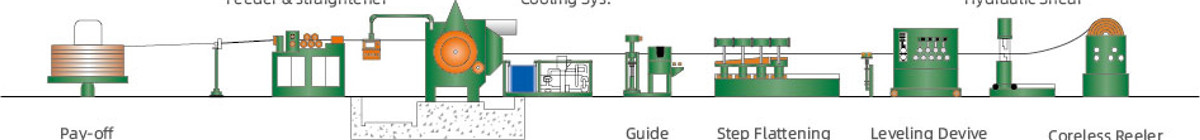

Mashiinka Qaboojiyaha Kahortagga Bixinta Lacag-bixinta Sys. Mashiinka Qaadista Qoob ka ciyaarka

2. Si aad u samayso baska naxaasta, wareega naxaasta iyo profile copper

| Qaabka | TLJ 350 | TLJ 350H | TLJ 400 | TLJ 400H | TLJ 500 | TLJ 630 |

| Matoorka ugu muhiimsan (kw) | 160 | 200 | 250 | 315 | 355 | 600 |

| usha quudinta dia. (mm) | 16 | 16 | 20 | 20 | 25 | 30 |

| max ballaca alaabta (mm) | 100 | 100 | 170 | 170 | 260 | 320 |

| ul alaabta dia.(mm) | 4.5-50 | 4.5-50 | 8-90 | 8-90 | 12-100 | 12-120 |

| aagga isdhaafka ah ee alaabta (mm2) | 15-1000 | 15-1000 | 75-2000 | 75-2000 | 300-3200 | 600-6400 |

| wax soo saarka (kg/saacaddii) | 780 | 950 | 1200 | 1500 | 1800 | 2800 |

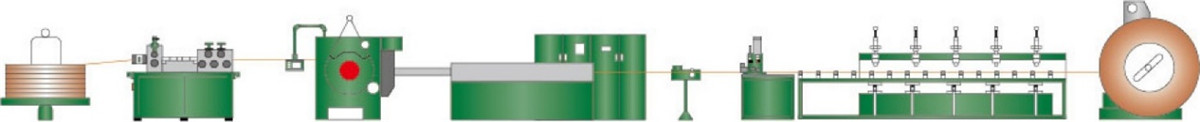

Qaabka Khadka Wax-soo-saarka

Feeder-off-off Feeder & toosiye Mashiinka qaboojinta Sys. Mishiinka Qaadista Fadhiga Alaabta Dhererka

3. Si aad u samayso baska copper, strip copper

| Qaabka | TLJ 500U | TLJ 600U |

| Matoorka ugu muhiimsan (kw) | 355 | 600 |

| usha quudinta dia. (mm) | 20 | 30 |

| max ballaca alaabta (mm) | 250 | 420 |

| max ballac ilaa saamiga dhumucda | 76 | 35 |

| dhumucda alaabta (mm) | 3-5 | 14-18 |

| wax soo saarka (kg/saacaddii) | 1000 | 3500 |

Qaabka Khadka Wax-soo-saarka

Quudinta usha daawaha naxaasta ah

Codsashada kirishbooyada commutator, naxaas maran, usha fosfoor ee naxaasta ah, fareemka sunta rasaasta, siliga xiriirka tareenka iwm.

| TLJ 350 | TLJ 400 | TLJ 500 | TLJ 630 | |

| maaddo | 1459/62/63/65 naxaas cu/Ag (AgsO.08%) | fosfoor naxaas ah (Pso.5%) cu/Ag (AgsO.3%) | magnesium copper (MgsO.5%) naxaasta birta (Feso.l% | magnesium copper (MgsO.7%) / Cucrzr |

| usha quudinta dia. (mm) | 12/12.5 | 20 | 20 | 25 |

| max ballaca alaabta (mm) | 30 | 150 (xarig naxaas ah oo lacag ah) | 100 (xarigga jir ee hogaanka:) | 320 |

| ul alaabta dia.(mm) | fosfoor kubbadda naxaasta: 10-40 | magnesium copperrod: 20-40 | magnesium copperrod: 20-40 | |

| wax soo saarka (kg/saacaddii) | 380 | 800-1000 | 1000-1200 | 1250/850 |

Qaabka Khadka Wax-soo-saarka

Feeder-off-off Feeder & toosiye Mashiinka qaboojinta Sys. Mashiinka Qaadista Ka-hortagga Dhererka

Quudinta usha aluminiumka

Dalbashada silig fidsan, baska baska, iyo kirishboyga profiled, tube wareegsan, MPE, iyo PFC Tubooyinka

| Qaabka | LLJ 300 | LLJ 300H | LLJ 350 | LLJ 400 |

| Matoorka ugu muhiimsan (kw) | 110 | 110 | 160 | 250 |

| usha quudinta dia. (mm) | 9.5 | 9.5 | 2*9.5/15 | 2*12/15 |

| max Balaadhka alaabta siliga fidsan (mm) | 30 | 30 | 170 | |

| Alaabta siliga fidsan aagga iskutallaabta (mm2) | 5-200 | 5-200 | 25-300 | 75-2000 |

| tuubada wareega dia. (mm) | 5-20 | 5-20 | 7-50 | |

| ballac tuubo fidsan (mm) | - | ≤40 | ≤70 | |

| silig fidsan/tuubo ka soo baxay (kg/h) | 160/160 | 280/240 | 260/260 | (600/900)/- |

Qaabka Khadka Wax-soo-saarka

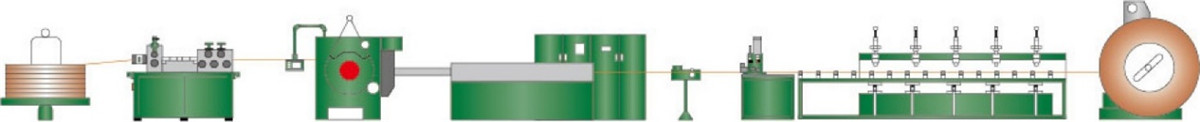

Toosiyaha lacag-bixinta ah ee nadiifinta Ultrasonic qaboojinta Sys qoob-ka-cayaarka Mashiinka Qaadista

Sawirka 217282