Fiilada waxtarka sare leh iyo Cable Extruders

Jilayaasha ugu muhiimsan

1, qaatay daawaynta aad u fiican halka daaweynta nitrogen ee fur iyo foosto, xasilloon oo nolol adeeg dheer.

2, nidaamka kuleylinta iyo qaboojinta ayaa si gaar ah loogu talagalay halka heerkulka lagu dejin karo in kala duwan ee 0-380 ℃ la kontoroolka-sax sare.

3, hawlgalka saaxiibtinimo ee PLC+ touch screen

4, L / D ratio ee 36: 1 codsiyada cable gaar ah (xunbo jirka iwm)

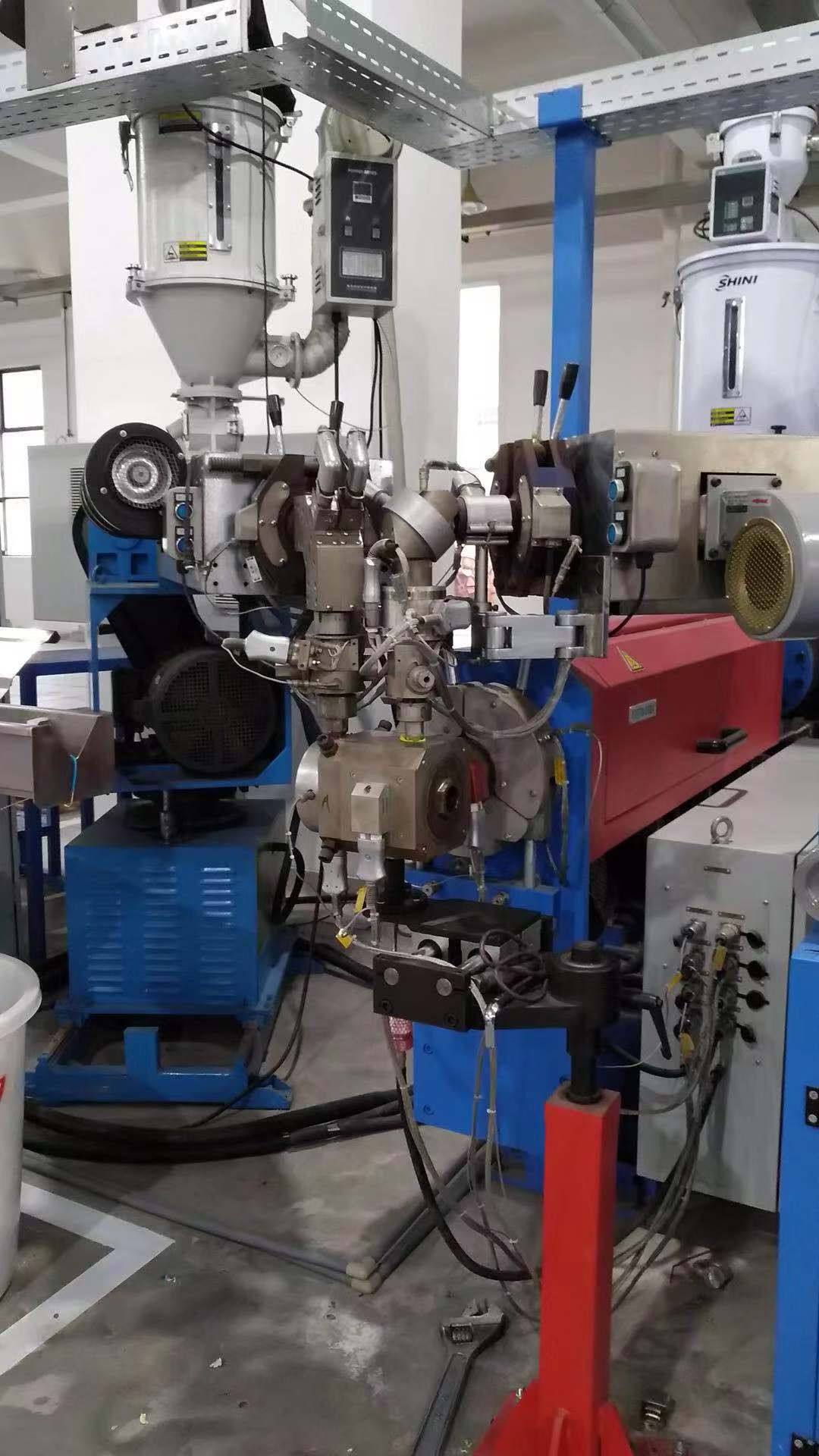

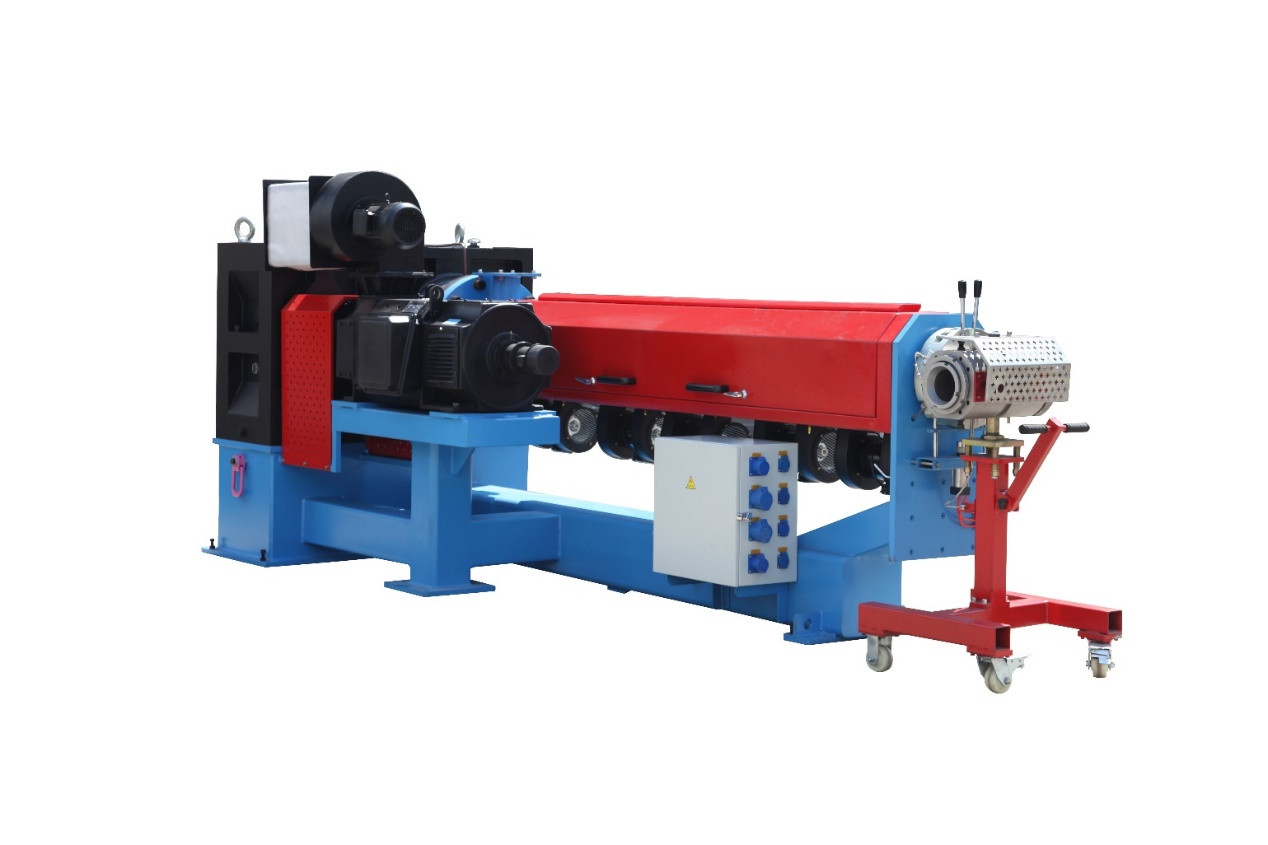

1.Mashiinka saarista waxtarka sare leh

Codsiga: Inta badan waxaa loo isticmaalaa dahaarka ama galka galka fiilooyinka iyo fiilooyinka

| Qaabka | Halbeegga maroodiga | Awoodda soo saarista (kg/saacaddii) | Awoodda ugu weyn ee matoorka (kw) | Dhexdhexaadiyaha siliga dibadda.(mm) | ||||

| Dia.(mm) | Saamiga L/D | Xawaaraha (rpm) | PVC | LDPE | LSHF | |||

| 30/25 | 30 | 25:1 | 20-120 | 50 | 30 | 35 | 11 | 0.2-1 |

| 40/25 | 40 | 25:1 | 20-120 | 60 | 40 | 45 | 15 | 0.4-3 |

| 50/25 | 50 | 25:1 | 20-120 | 120 | 80 | 90 | 18.5 | 0.8-5 |

| 60/25 | 60 | 25:1 | 15-120 | 200 | 140 | 150 | 30 | 1.5-8 |

| 70/25 | 70 | 25:1 | 15-120 | 300 | 180 | 200 | 45 | 2-15 |

| 75/25 | 75 | 25:1 | 15-120 | 300 | 180 | 200 | 90 | 2.5-20 |

| 80/25 | 80 | 25:1 | 10-120 | 350 | 240 | 270 | 90 | 3-30 |

| 90/25 | 90 | 25:1 | 10-120 | 450 | 300 | 350 | 110 | 5-50 |

| 100/25 | 100 | 25:1 | 5-100 | 550 | 370 | 420 | 110 | 8-80 |

| 120/25 | 120 | 25:1 | 5-90 | 800 | 470 | 540 | 132 | 8-80 |

| 150/25 | 150 | 25:1 | 5-90 | 1200 | 750 | 700 | 250 | 35-140 |

| 180/25 | 180 | 25:1 | 5-90 | 1300 | 1000 | 800 | 250 | 50-160 |

| 200/25 | 200 | 25:1 | 5-90 | 1600 | 1100 | 1200 | 315 | 90-200 |

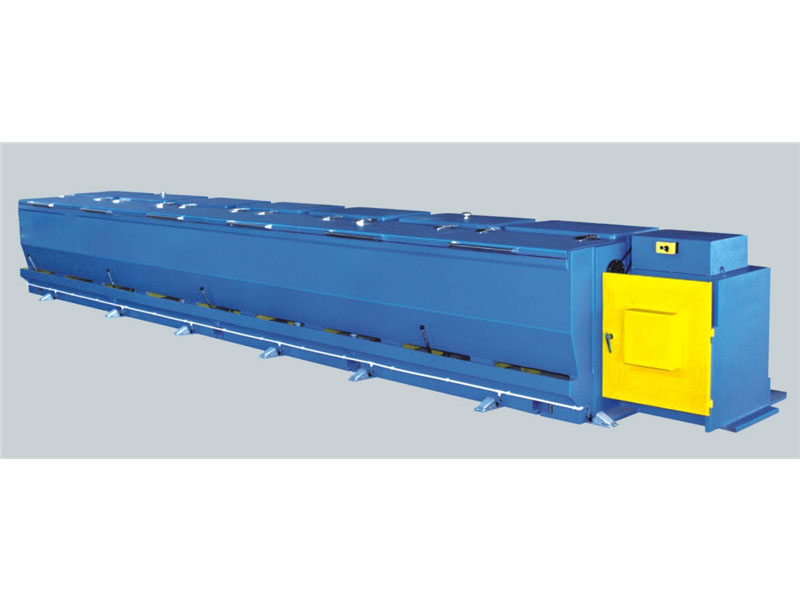

2.Double line co-extrusion line

Codsiga: Khadka isku-dhafka ah wuxuu ku habboon yahay qiiqa yar ee halogen-ka bilaashka ah, extrusion XLPE, oo inta badan loo isticmaalo wax soo saarka fiilooyinka saldhigga tamarta nukliyeerka, iwm.

| Qaabka | Halbeegga maroodiga | Awoodda soo saarista (kg/saacaddii) | Xadhkaha gudaha ee siliga. (mm) | dia silig outlet. (mm) | Xawaaraha khadka (m/min) | |

| Dia.(mm) | Saamiga L/D | |||||

| 50+35 | 50+35 | 25:1 | 70 | 0.6-4.0 | 1.0-4.5 | 500 |

| 60+35 | 60+35 | 25:1 | 100 | 0.8-8.0 | 1.0-10.0 | 500 |

| 65+40 | 65+40 | 25:1 | 120 | 0.8-10.0 | 1.0-12.0 | 500 |

| 70+40 | 70+40 | 25:1 | 150 | 1.5-12.0 | 2.0-16.0 | 500 |

| 80+50 | 80+50 | 25:1 | 200 | 2.0-20.0 | 4.0-25.0 | 450 |

| 90+50 | 90+50 | 25:1 | 250 | 3.0-25.0 | 6.0-35.0 | 400 |

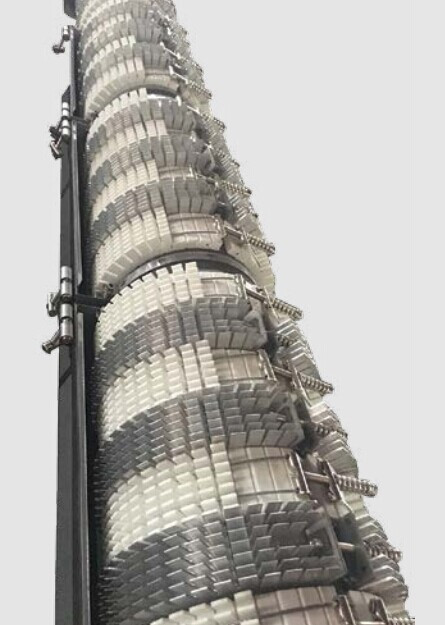

3.Triple-extrusion line

Codsiga: Khadka saddex-geesoodka ah wuxuu ku habboon yahay qiiqa yar ee halogen-ka bilaashka ah, extrusion XLPE, oo inta badan loo isticmaalo soosaarka fiilooyinka saldhigga tamarta nukliyeerka, iwm.

| Qaabka | Halbeegga maroodiga | Awoodda soo saarista (kg/saacaddii) | Xadhkaha gudaha ee siliga. (mm) | Xawaaraha khadka (m/min) | |

| Dia.(mm) | Saamiga L/D | ||||

| 65+40+35 | 65+40+35 | 25:1 | 120/40/30 | 0.8-10.0 | 500 |

| 70+40+35 | 70+40+35 | 25:1 | 180/40/30 | 1.5-12.0 | 500 |

| 80+50+40 | 80+50+40 | 25:1 | 250/40/30 | 2.0-20.0 | 450 |

| 90+50+40 | 90+50+40 | 25:1 | 350/100/40 | 3.0-25.0 | 400 |