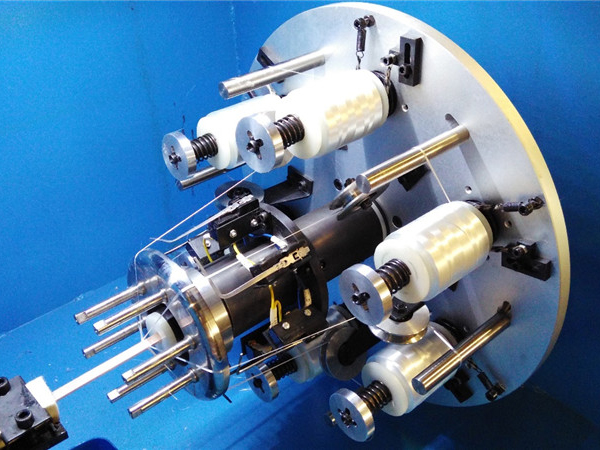

Mashiinka sawiridda fiilada birta qoyan

Faahfaahinta Alaabta Tags Product Qaabka mashiinka

LT21/200

LT17/250

LT21/350

LT15/450

Walxaha siliga soo gala

Sare / Dhexdhexaad / Silig kaarboon ah oo hooseeya;

Silig bir ah; Siligga birta Alloy

Baas-gacmeedka

21

17

21

15

Siliga gudaha Dia.

1.2-0.9mm

1.8-2.4mm

1.8-2.8mm

2.6-3.8mm

Siliga dibadda Dia.

0.4-0.15mm

0.6-0.35mm

0.5-1.2mm

1.2-1.8mm

Xawaaraha sawirka

15m/s

10

8m/s

10m/s

Awoodda matoorka

22KW

30KW

55KW

90KW

Farsamaynta ugu weyn

NSK caalamiga ah, SKF xadhkaha ama macmiilka ayaa loo baahan yahay

Kii hore: Mashiinka Sawirka Siliga Biraha-Mashiinnada Caawiya Xiga: Mashiinka Sawirka Toosan ee leexday Alaabooyinka la xidhiidha Khadka waxa uu ka kooban yahay mishiinada soo socda ● Bixinta gariiradda nooca toosan ama toosan ● Qalajiyaha makaanikada & suunka suunka ciid ● Cutubka biyo raacida & cutubka qalajinta korantada ● Qaybta daahan borax ● Sadex jeer oo dib loo warshadeeyay biyo luqluqashada & cutubka qajaarka ● Cutubka dahaarka naxaasta qaadashada ● Lakabka dib u rogida...

Xogta ugu muhiimsan ee farsamada dhexroorka kaarida wareega: 2.5mm-6.0mm Aagga kirishtaanka fidsan: 5mm²—80 mm² (Balac: 4mm-16mm, Dhumucda: 0.8mm-5.0mm) Xawaaraha wareega: max. 800 rpm Xawaaraha khadka: ugu badnaan. 8 m/daqiiqo Astaamaha gaarka ah Servo wadida madaxa dabaylaha otomaatig u joogso marka fiberglass jabo Naqshad qaabdhismeed adag iyo qaab-dhismeedka qaabaysan si loo baabi'iyo is dhexgalka gariir PLC kontoroolka iyo dulmarka hawlgalka shaashadda taabashada

Wax-soo-saarka • Awoodda wax-soo-saarka oo sarreeya oo leh siligga is haysta Waxtarka xawaaraha [m/sic] 30 dhexda Ø kala duwan [mm] 2.35-3.5 Max. spool flange dia. (mm) 1000 Max. Awoodda matoorka (kg) 2000 Awoodda ugu weyn ee matoorka (kw) 45 Cabbirka mishiinka (L*W*H) (m) 2.6*1.9*1.7 Miisaanka (kg) Qiyaastii 6000 Habka Traverse Kubbada jihada wareegta ee ay maamusho mootada wareega wareega nooca Hi. ..

● qaanso u bood nooca strander si aad u soo saarto xargaha heerka caalamiga ah. ● Laba-jibbaaran oo koofiyad jiidaya ilaa 16 tan. ● Foornada la dhaqaajin karo oo loogu talagalay xasilinta heerkulbeegga siliga siligga ● Haanta biyaha ee qaboojinta siliga oo tayo sare leh. cabbirka alaabta mm 9.53; 11.1; 12.7; 15.24; 17.8 Xawaaraha shaqada ee xariiqda m/daqadda...

Astaamaha ● Kabtan la been abuurtay ama la shubay oo adag HRC 58-62. ● Gudbinta waxtarka sare leh oo leh sanduuqa qalabka ama suunka. ● Sanduuqa dhinta ee la dhaqaajin karo si ay u fududaato hagaajinta iyo beddelka dhinta ee fudud. ● Habka qaboojinta waxqabadka sare ee sanduuqa capstan iyo dhimashada gariiradda ● Fi...

Faa'iidooyinka 1, qallafsanaanta caaga ah ee usha quudinta ee hoos timaada xoogga is-jiidka iyo heerkulka sare ee baabi'inta cilladaha gudaha ee usha lafteeda si buuxda si loo hubiyo in alaabta ugu dambeysa ay leedahay wax-soo-saarka badeecada ugu fiican iyo saxnaanta cabbirka sare. 2, aan preheating ama annealing, alaabta tayada wanaagsan helay by habka extrusion isticmaalka tamarta hoose. 3, oo leh...